Established in 1994, Zee Hygine Products Pvt. Ltd. is one of India’s most experienced third-party manufacturers in the cosmetics, personal care, and ayurvedic industry. With over 30 years of legacy, we specialize in developing and manufacturing customized solutions across a wide range of categories including Skin Care, Hair Care, Baby Care, Oral Care, Home Care and Herbal Care.

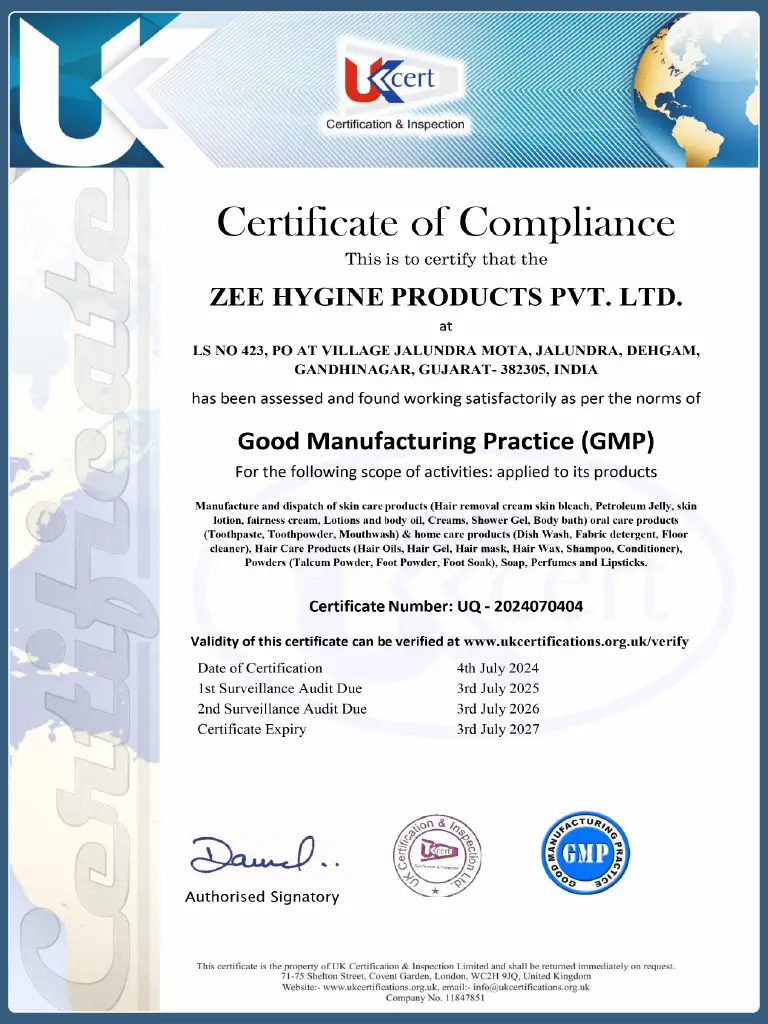

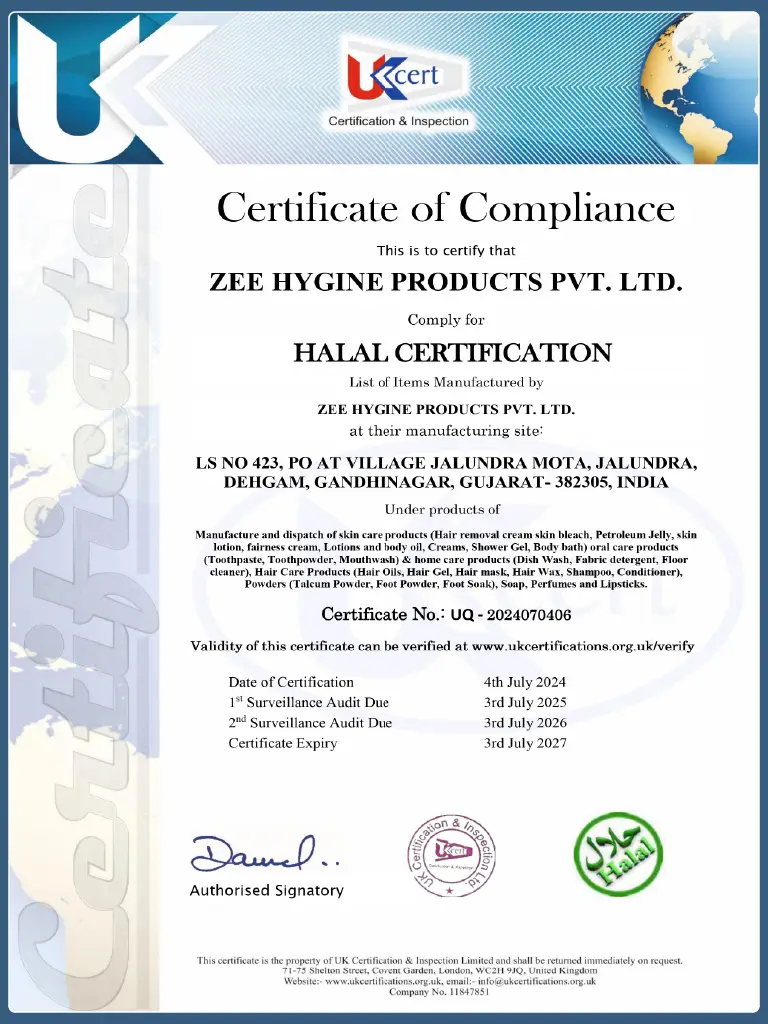

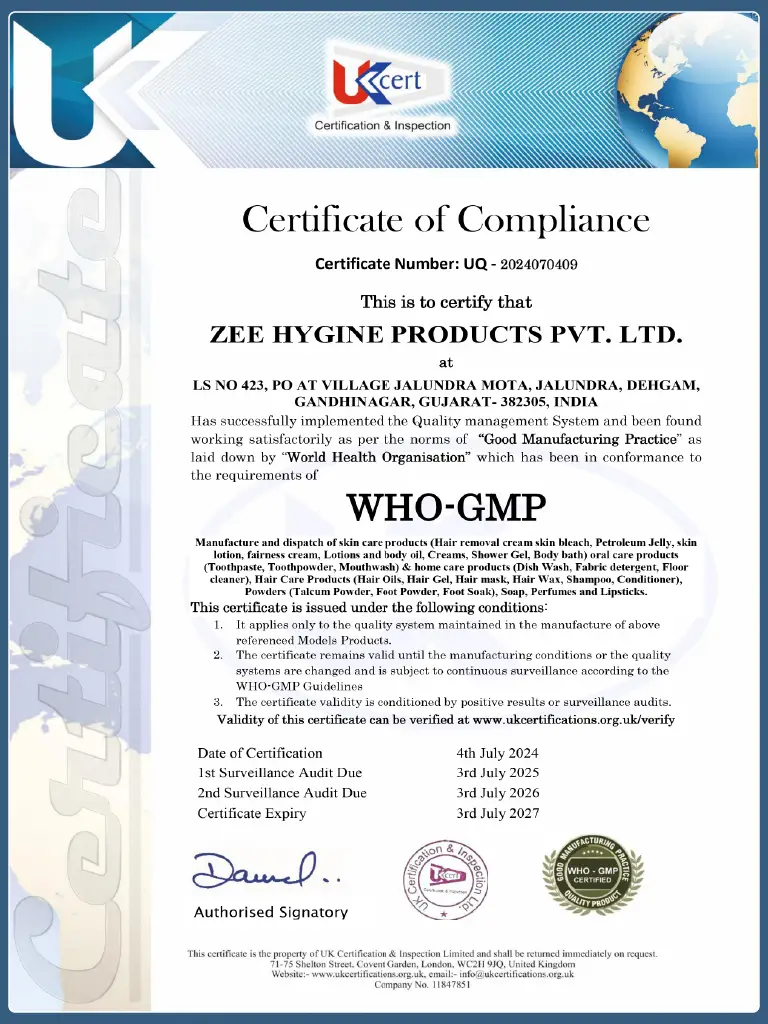

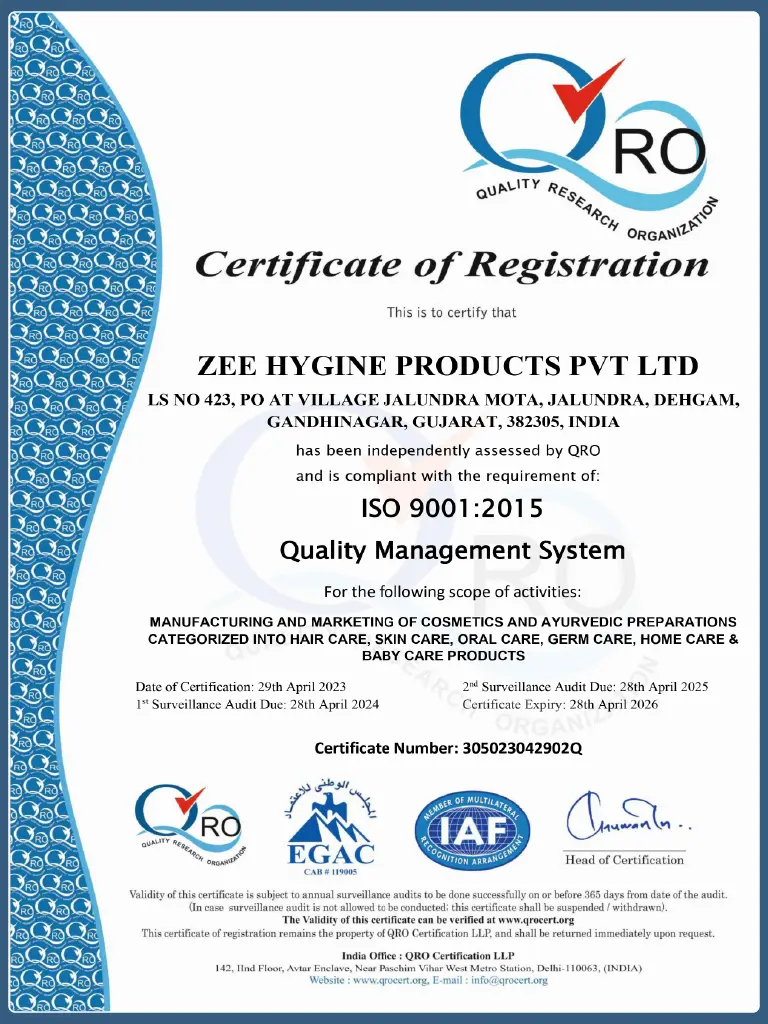

Located in Dahegam, Gandhinagar (Gujarat), our production facility spans over 35,000 sq. ft., purpose-built to meet GMP compliance and certified under ISO 9001:2015, ISO 22716 (Cosmetic GMP), and HALAL standards. We support businesses of all sizes — from startup brands to established global players — by offering end-to-end services from R&D and formulation to bulk manufacturing, filling, and packaging.

Our strength lies in our ability to combine custom formulation flexibility with large-scale output. With advanced mixing, filling, and packaging equipment, we can produce:

“To position ourselves as a globally recognized leader in personal hygiene and cosmetic manufacturing.”

“To deliver high-quality, customized cosmetic and ayurvedic products through advanced manufacturing, innovative R&D, and reliable private label solutions that drive lasting partnerships.”

At Zee Hygine, our operations are guided by a strong internal philosophy rooted in quality, responsibility, and progress. We are committed:

Our facility is equipped to deliver both flexibility and scale — whether you're developing niche formulations or producing large volumes. We operate fully automated/Semi Automated lines and specialized equipment tailored to different product categories

| Equipment | Capacity / Speed | Daily Output | Application |

|---|---|---|---|

| Contra Rotary Mixer & Gel Kettle | 750 kg | 4,000 kg | Toothpaste |

| Indo German Mixers (x2) | 250 kg each | 3,000 kg | Cosmetic Products |

| Oil Manufacturing Mixers (x2) | 400–500 kg each | 6,000 kg | Hair & Body Oils |

| Petroleum Jelly Vessels (x3) | 400–500 kg each | 6,000 kg | Petroleum Jelly |

| Volumetric Filling Machines (x5) (Total 20 nozzles) |

20–60 BPM | 25,000–1,00,000 pcs | Bottles, jars, tubes (30–1000 ml) |

| Tube Filling Machines (x3) (Total 4 nozzles) |

30–120 TPM | Up to 79,200 pcs | Tubes (20–200 gm) |

| Powder Blender + Filling Machine | 100 kg / 20 BPM | Up to 2,400 kg / 20,000 pcs | Powdered products |

| Labelling Machines (x2) | 130 BPM | Up to 150,000 pcs | All formats (label size dependent) |

| Cream & Pouch Filling Machines (x2) | 20–96 Pouch/min | Up to 1.25 lakh pouches | Sachets, pouches (5–70 ml/gm) |

Our dedicated R&D and Quality Control teams ensure that every formulation meets client specifications, product claims, and regulatory standards. From early-stage prototypes to final product validation, we maintain rigorous testing protocols and full traceability.